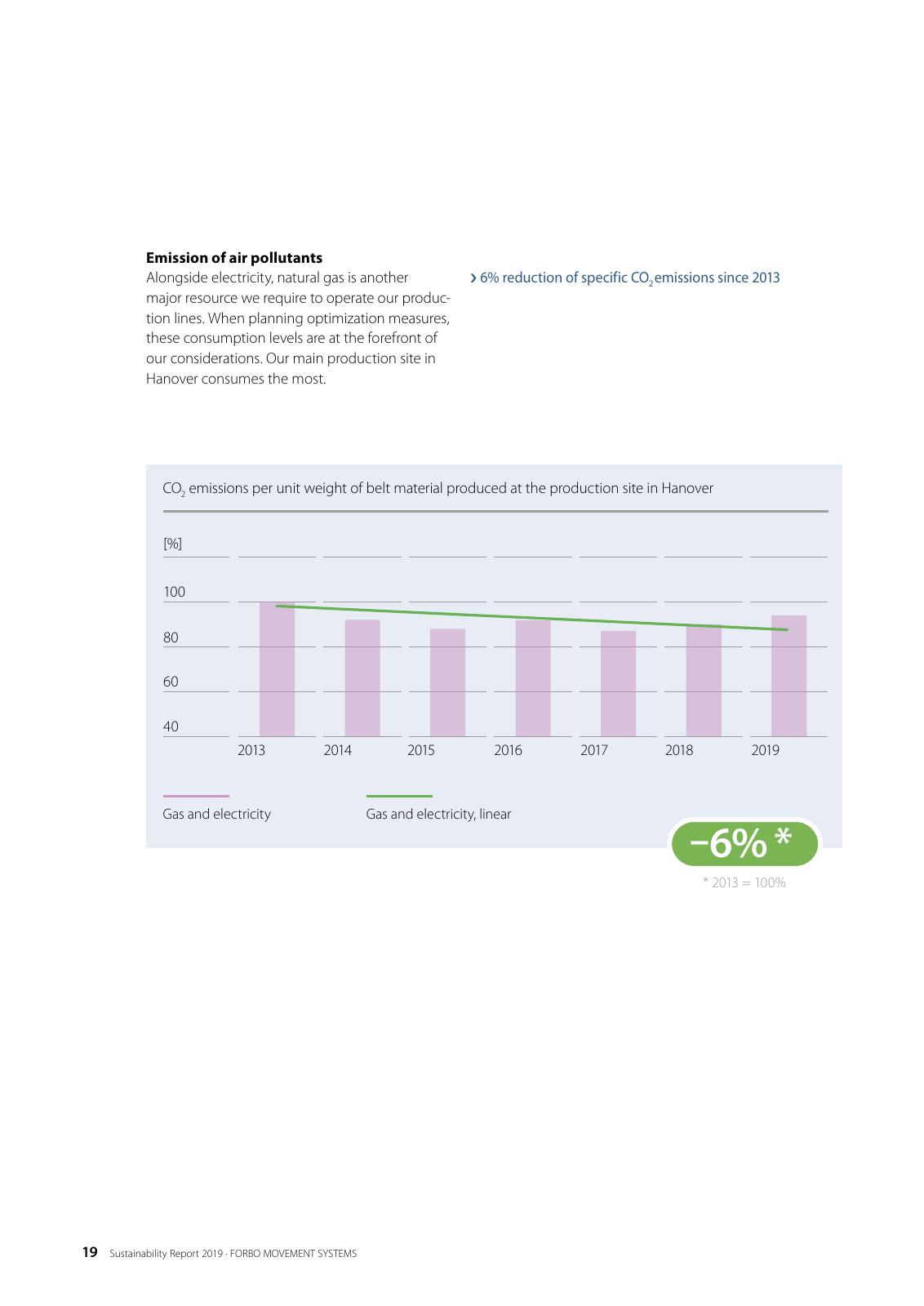

19 Sustainability Report 2016 FORBO MOVEMENT SYSTEMS Emission of air pollutants In addition to electrical energy the company requires natural gas in particular in order to operate its production facilities When planning optimization measures these consumption quantities are at the forefront of our considerations Our main production site in Hanover accounts for the greatest consumption quantities By pursuing continuous improvements in all units through energy coupling of exhaust streams and through the separation of exhaust air volumes for combustion or filtration we are able to significant ly reduce energy quantities used and therefore our CO2 emissions as well Bio Belt In our Bio Belt conveyor belts we have largely replaced petroleum based raw materials and synthetic plastics with renewable raw materials derived from plants Thanks to the possibility of subsequent biodegradation these belts even create one of the essential prerequisites for fulfillment of the Cradle to Cradle principle the patented alternative to 100 synthetic belts 8 reduction of specific CO2 emissions since 2013 CO2 emissions per unit weight of belt material produced at the main production site in Hanover Gas and electrical energy Gas and electrical energy linear 2013 2014 2015 2016 100 40 60 80 8

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.