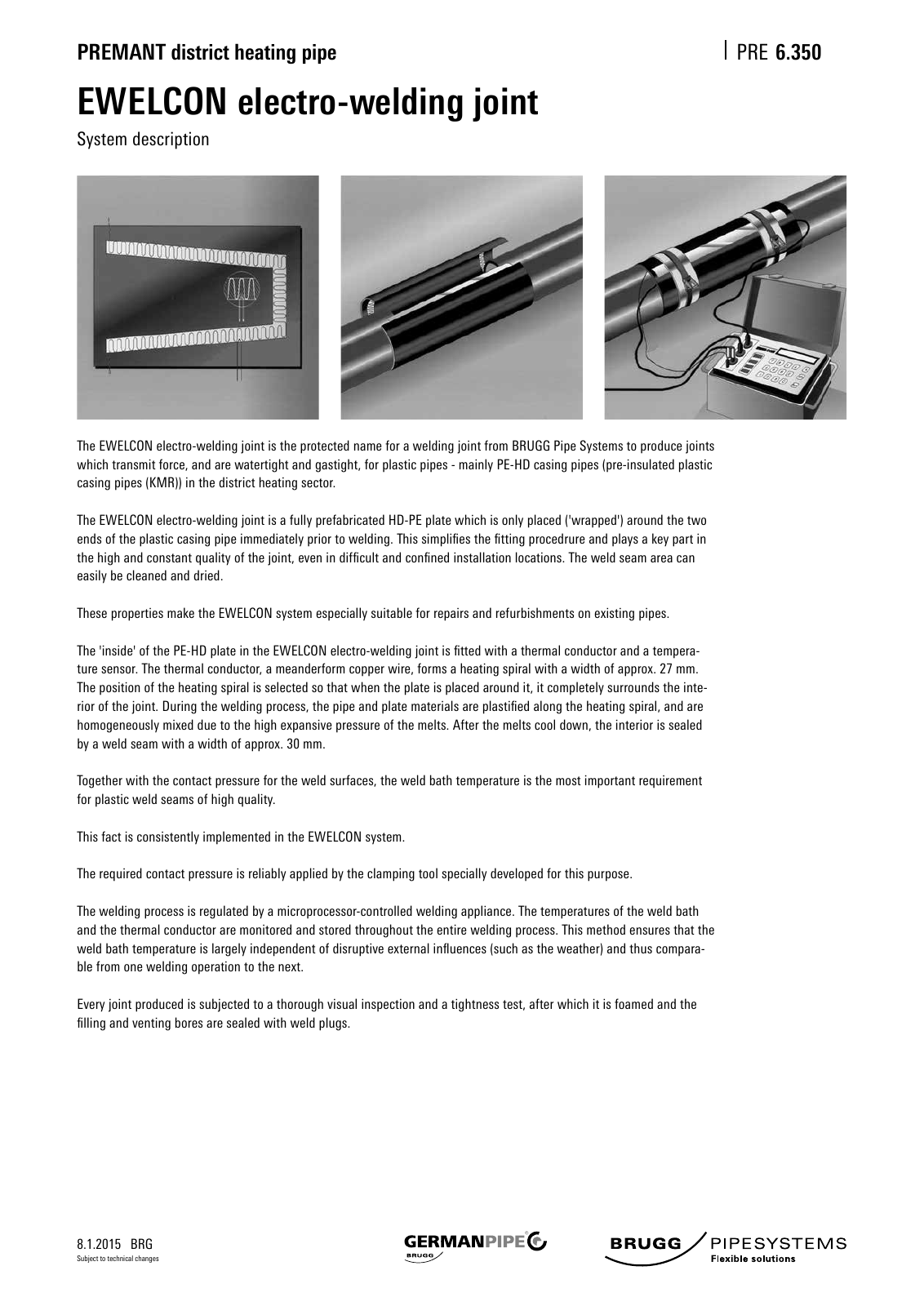

8 1 2015 BRG PREMANT district heating pipe PRE Subject to technical changes 6 350 EWELCON electro welding joint System description The EWELCON electro welding joint is the protected name for a welding joint from BRUGG Pipe Systems to produce joints which transmit force and are watertight and gastight for plastic pipes mainly PE HD casing pipes pre insulated plastic casing pipes KMR in the district heating sector The EWELCON electro welding joint is a fully prefabricated HD PE plate which is only placed wrapped around the two ends of the plastic casing pipe immediately prior to welding This simplifies the fitting procedrure and plays a key part in the high and constant quality of the joint even in difficult and confined installation locations The weld seam area can easily be cleaned and dried These properties make the EWELCON system especially suitable for repairs and refurbishments on existing pipes The inside of the PE HD plate in the EWELCON electro welding joint is fitted with a thermal conductor and a tempera ture sensor The thermal conductor a meanderform copper wire forms a heating spiral with a width of approx 27 mm The position of the heating spiral is selected so that when the plate is placed around it it completely surrounds the inte rior of the joint During the welding process the pipe and plate materials are plastified along the heating spiral and are homogeneously mixed due to the high expansive pressure of the melts After the melts cool down the interior is sealed by a weld seam with a width of approx 30 mm Together with the contact pressure for the weld surfaces the weld bath temperature is the most important requirement for plastic weld seams of high quality This fact is consistently implemented in the EWELCON system The required contact pressure is reliably applied by the clamping tool specially developed for this purpose The welding process is regulated by a microprocessor controlled welding appliance The temperatures of the weld bath and the thermal conductor are monitored and stored throughout the entire welding process This method ensures that the weld bath temperature is largely independent of disruptive external influences such as the weather and thus compara ble from one welding operation to the next Every joint produced is subjected to a thorough visual inspection and a tightness test after which it is foamed and the filling and venting bores are sealed with weld plugs

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.