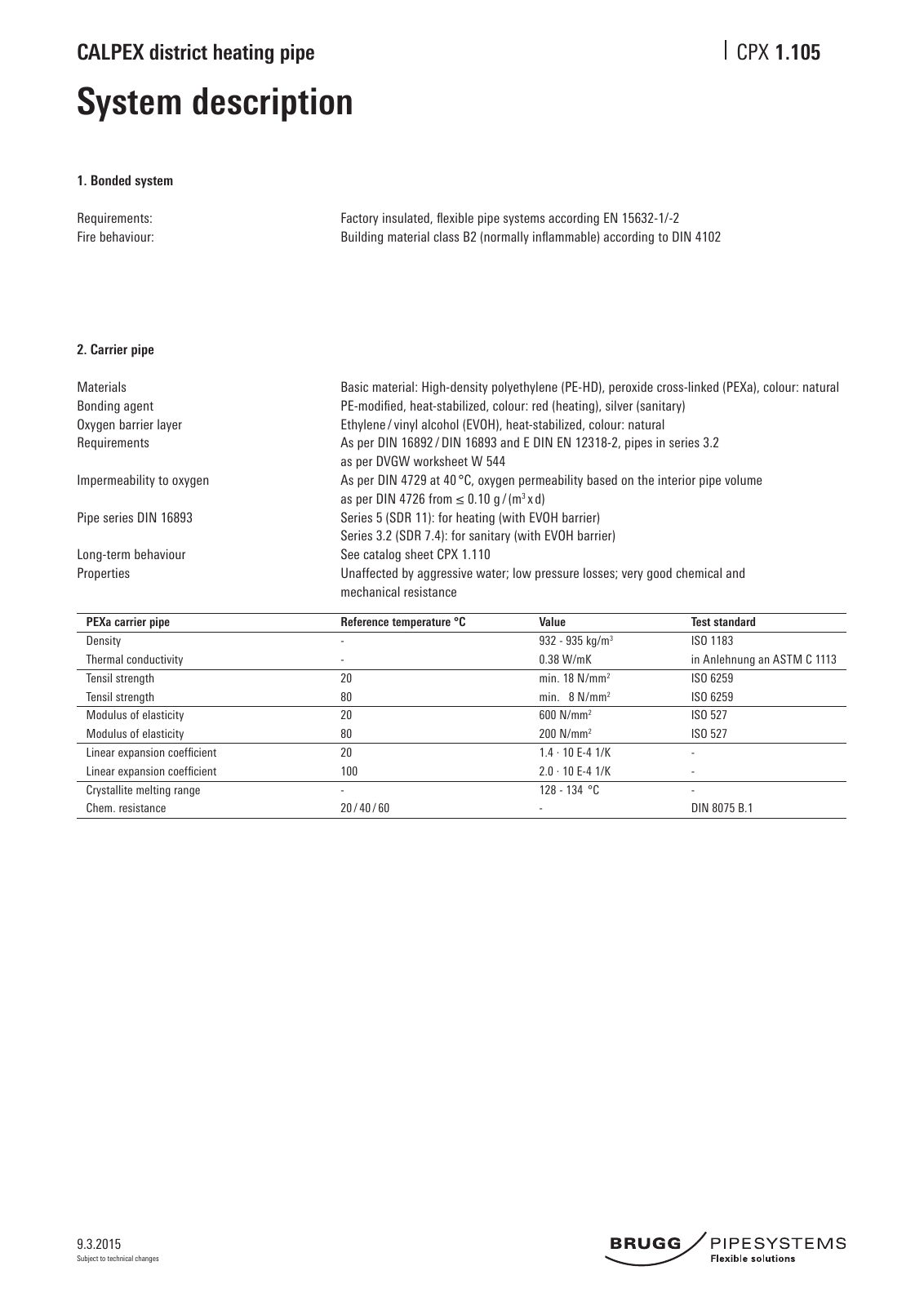

9 3 2015 CALPEX district heating pipe CPX Subject to technical changes PEXa carrier pipe Reference temperature C Value Test standard Density 932 935 kg m3 ISO 1183 Thermal conductivity 0 38 W mK in Anlehnung an ASTM C 1113 Tensil strength 20 min 18 N mm2 ISO 6259 Tensil strength 80 min 8 N mm2 ISO 6259 Modulus of elasticity 20 600 N mm2 ISO 527 Modulus of elasticity 80 200 N mm2 ISO 527 Linear expansion coefficient 20 1 4 10 E 4 1 K Linear expansion coefficient 100 2 0 10 E 4 1 K Crystallite melting range 128 134 C Chem resistance 20 40 60 DIN 8075 B 1 System description 2 Carrier pipe Materials Basic material High density polyethylene PE HD peroxide cross linked PEXa colour natural Bonding agent PE modified heat stabilized colour red heating silver sanitary Oxygen barrier layer Ethylene vinyl alcohol EVOH heat stabilized colour natural Requirements As per DIN 16892 DIN 16893 and E DIN EN 12318 2 pipes in series 3 2 as per DVGW worksheet W 544 Impermeability to oxygen As per DIN 4729 at 40 C oxygen permeability based on the interior pipe volume as per DIN 4726 from 0 10 g m3 x d Pipe series DIN 16893 Series 5 SDR 11 for heating with EVOH barrier Series 3 2 SDR 7 4 for sanitary with EVOH barrier Long term behaviour See catalog sheet CPX 1 110 Properties Unaffected by aggressive water low pressure losses very good chemical and mechanical resistance 1 105 1 Bonded system Requirements Factory insulated flexible pipe systems according EN 15632 1 2 Fire behaviour Building material class B2 normally inflammable according to DIN 4102

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.