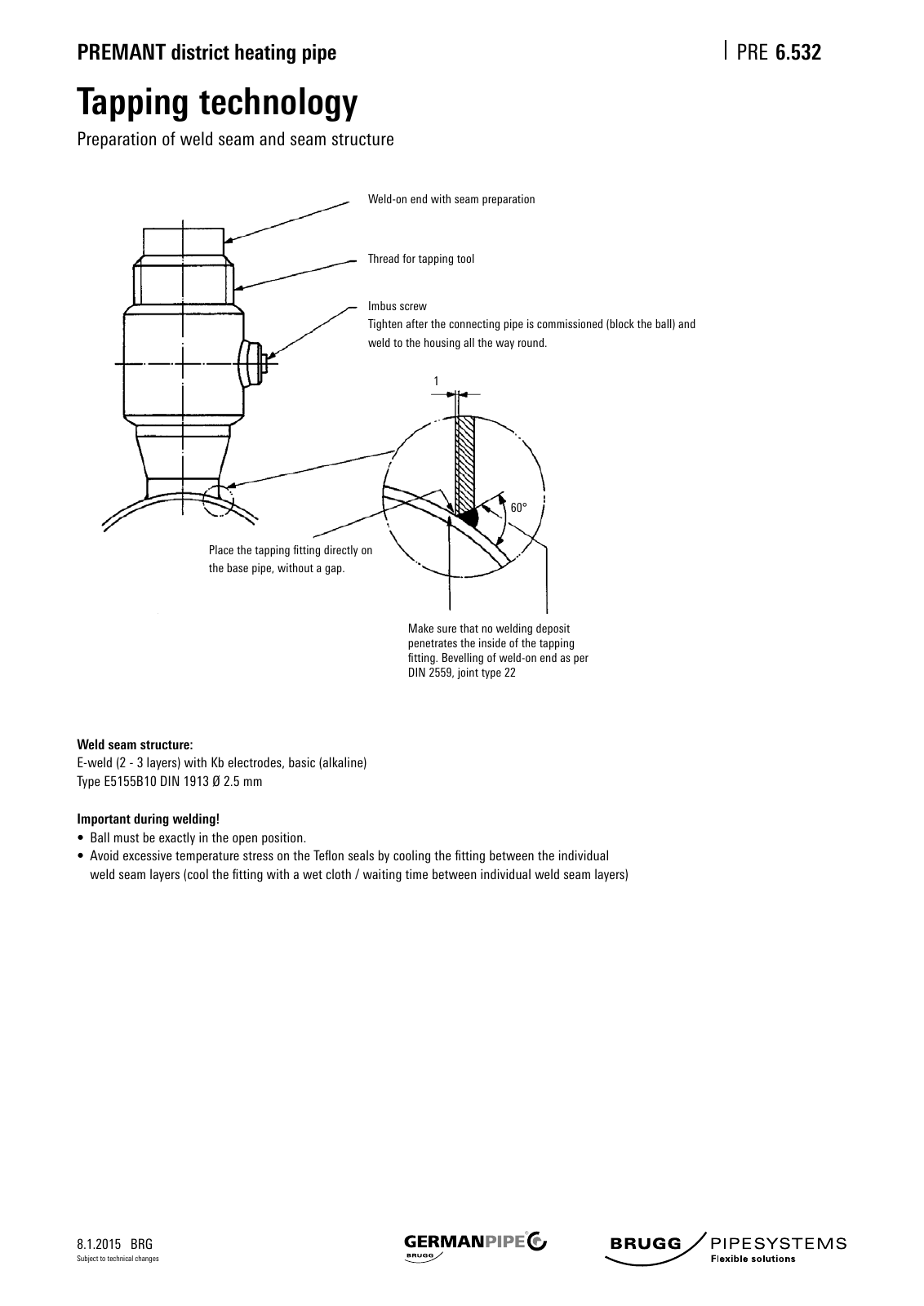

8 1 2015 BRG PREMANT district heating pipe PRE Subject to technical changes 6 532 Tapping technology Preparation of weld seam and seam structure Weld on end with seam preparation Thread for tapping tool Imbus screw Tighten after the connecting pipe is commissioned block the ball and weld to the housing all the way round Place the tapping fitting directly on the base pipe without a gap Weld seam structure E weld 2 3 layers with Kb electrodes basic alkaline Type E5155B10 DIN 1913 Ø 2 5 mm Important during welding Ball must be exactly in the open position Avoid excessive temperature stress on the Teflon seals by cooling the fitting between the individual weld seam layers cool the fitting with a wet cloth waiting time between individual weld seam layers Make sure that no welding deposit penetrates the inside of the tapping fitting Bevelling of weld on end as per DIN 2559 joint type 22 1 60

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.