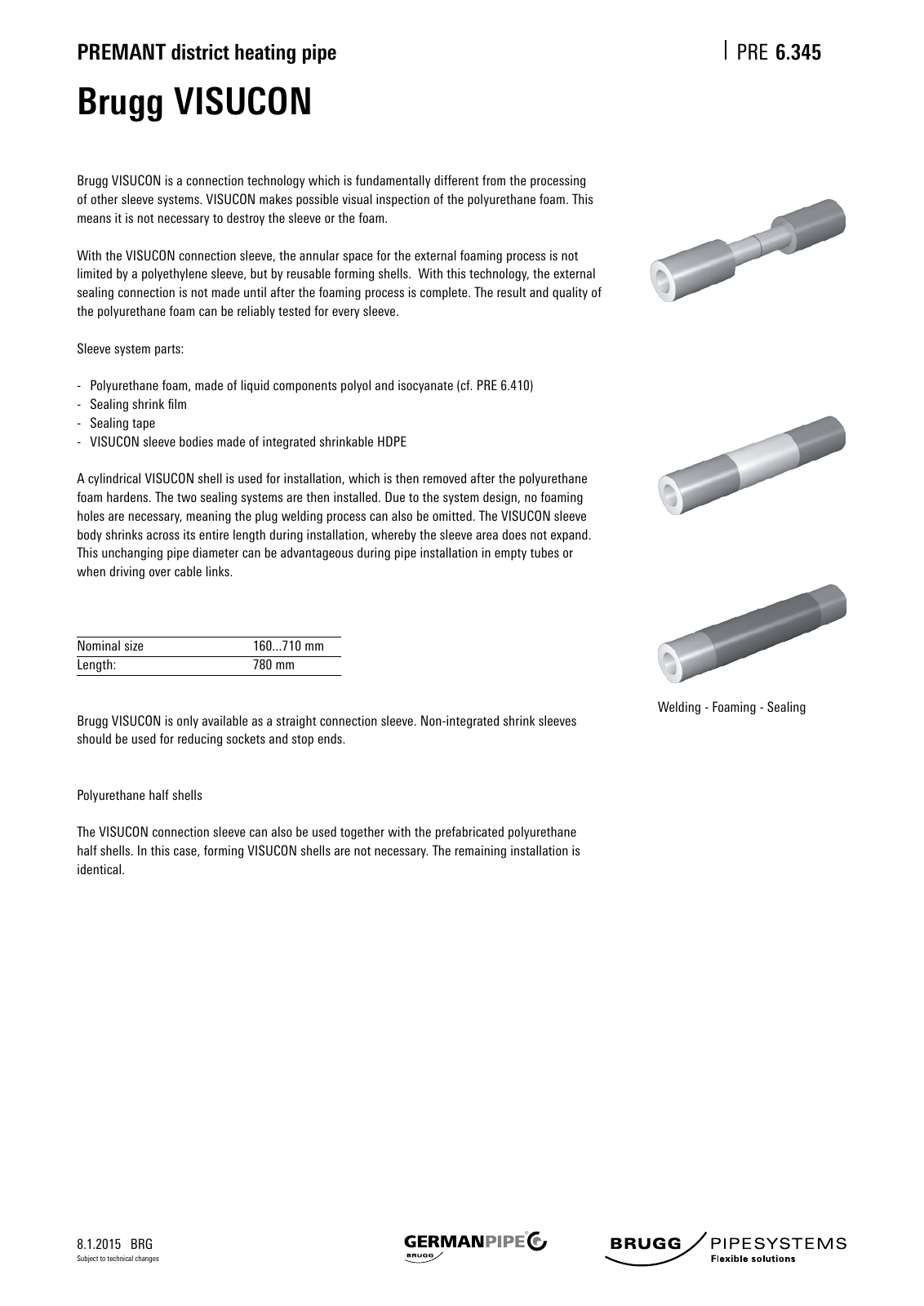

8 1 2015 BRG PREMANT district heating pipe PRE Subject to technical changes 6 345 Brugg VISUCON Brugg VISUCON is a connection technology which is fundamentally different from the processing of other sleeve systems VISUCON makes possible visual inspection of the polyurethane foam This means it is not necessary to destroy the sleeve or the foam With the VISUCON connection sleeve the annular space for the external foaming process is not limited by a polyethylene sleeve but by reusable forming shells With this technology the external sealing connection is not made until after the foaming process is complete The result and quality of the polyurethane foam can be reliably tested for every sleeve Sleeve system parts Polyurethane foam made of liquid components polyol and isocyanate cf PRE 6 410 Sealing shrink film Sealing tape VISUCON sleeve bodies made of integrated shrinkable HDPE A cylindrical VISUCON shell is used for installation which is then removed after the polyurethane foam hardens The two sealing systems are then installed Due to the system design no foaming holes are necessary meaning the plug welding process can also be omitted The VISUCON sleeve body shrinks across its entire length during installation whereby the sleeve area does not expand This unchanging pipe diameter can be advantageous during pipe installation in empty tubes or when driving over cable links Nominal size 160 710 mm Length 780 mm Brugg VISUCON is only available as a straight connection sleeve Non integrated shrink sleeves should be used for reducing sockets and stop ends Polyurethane half shells The VISUCON connection sleeve can also be used together with the prefabricated polyurethane half shells In this case forming VISUCON shells are not necessary The remaining installation is identical Welding Foaming Sealing

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.