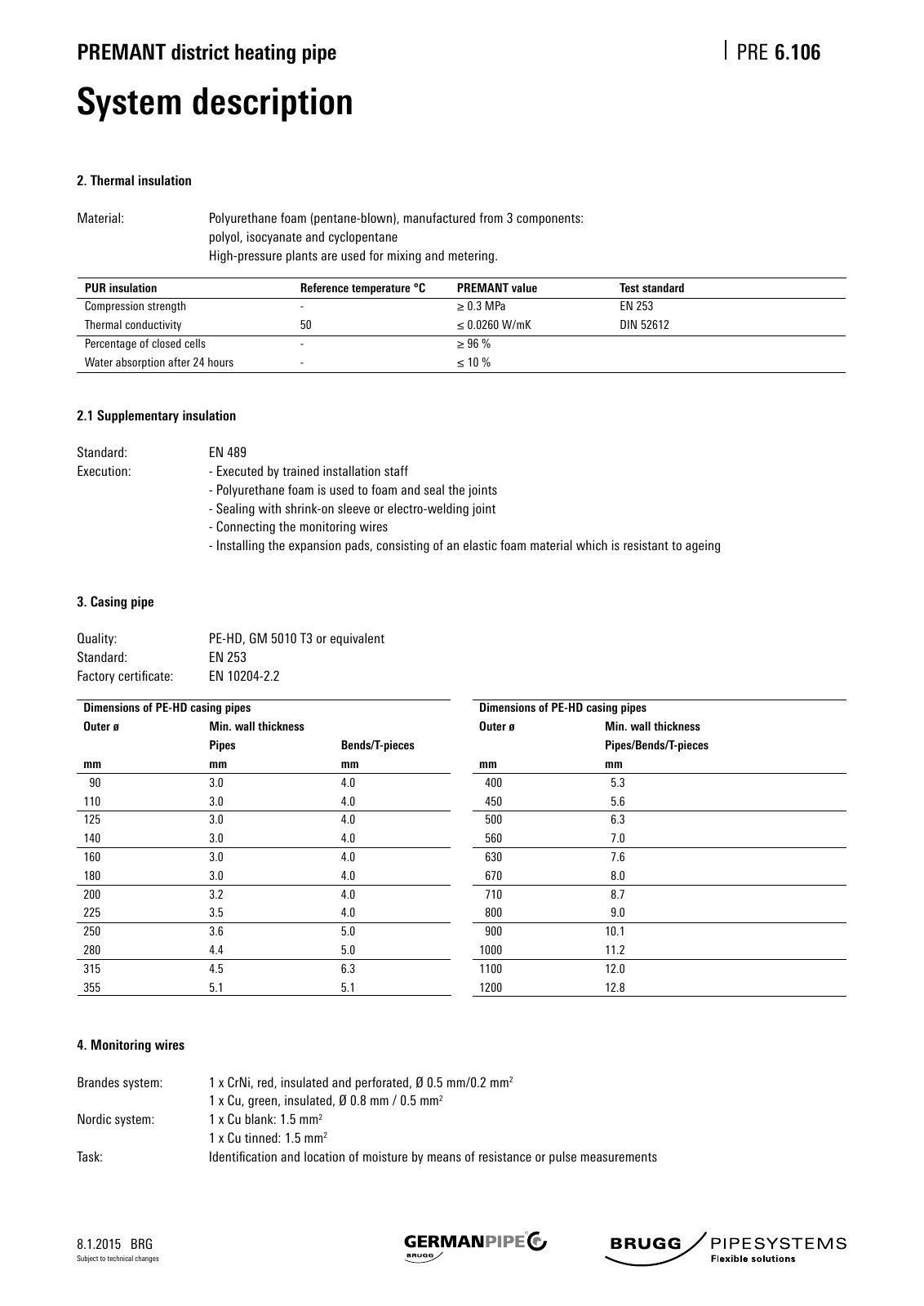

8 1 2015 BRG PREMANT district heating pipe PRE Subject to technical changes System description 6 106 4 Monitoring wires Brandes system 1 x CrNi red insulated and perforated Ø 0 5 mm 0 2 mm2 1 x Cu green insulated Ø 0 8 mm 0 5 mm2 Nordic system 1 x Cu blank 1 5 mm2 1 x Cu tinned 1 5 mm2 Task Identification and location of moisture by means of resistance or pulse measurements 2 Thermal insulation Material Polyurethane foam pentane blown manufactured from 3 components polyol isocyanate and cyclopentane High pressure plants are used for mixing and metering 2 1 Supplementary insulation Standard EN 489 Execution Executed by trained installation staff Polyurethane foam is used to foam and seal the joints Sealing with shrink on sleeve or electro welding joint Connecting the monitoring wires Installing the expansion pads consisting of an elastic foam material which is resistant to ageing 3 Casing pipe Quality PE HD GM 5010 T3 or equivalent Standard EN 253 Factory certificate EN 10204 2 2 PUR insulation Reference temperature C PREMANT value Test standard Compression strength 0 3 MPa EN 253 Thermal conductivity 50 0 0260 W mK DIN 52612 Percentage of closed cells 96 Water absorption after 24 hours 10 Dimensions of PE HD casing pipes Outer ø Min wall thickness Pipes Bends T pieces mm mm 400 5 3 450 5 6 500 6 3 560 7 0 630 7 6 670 8 0 710 8 7 800 9 0 900 10 1 1000 11 2 1100 12 0 1200 12 8 Dimensions of PE HD casing pipes Outer ø Min wall thickness Pipes Bends T pieces mm mm mm 90 3 0 4 0 110 3 0 4 0 125 3 0 4 0 140 3 0 4 0 160 3 0 4 0 180 3 0 4 0 200 3 2 4 0 225 3 5 4 0 250 3 6 5 0 280 4 4 5 0 315 4 5 6 3 355 5 1 5 1

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.