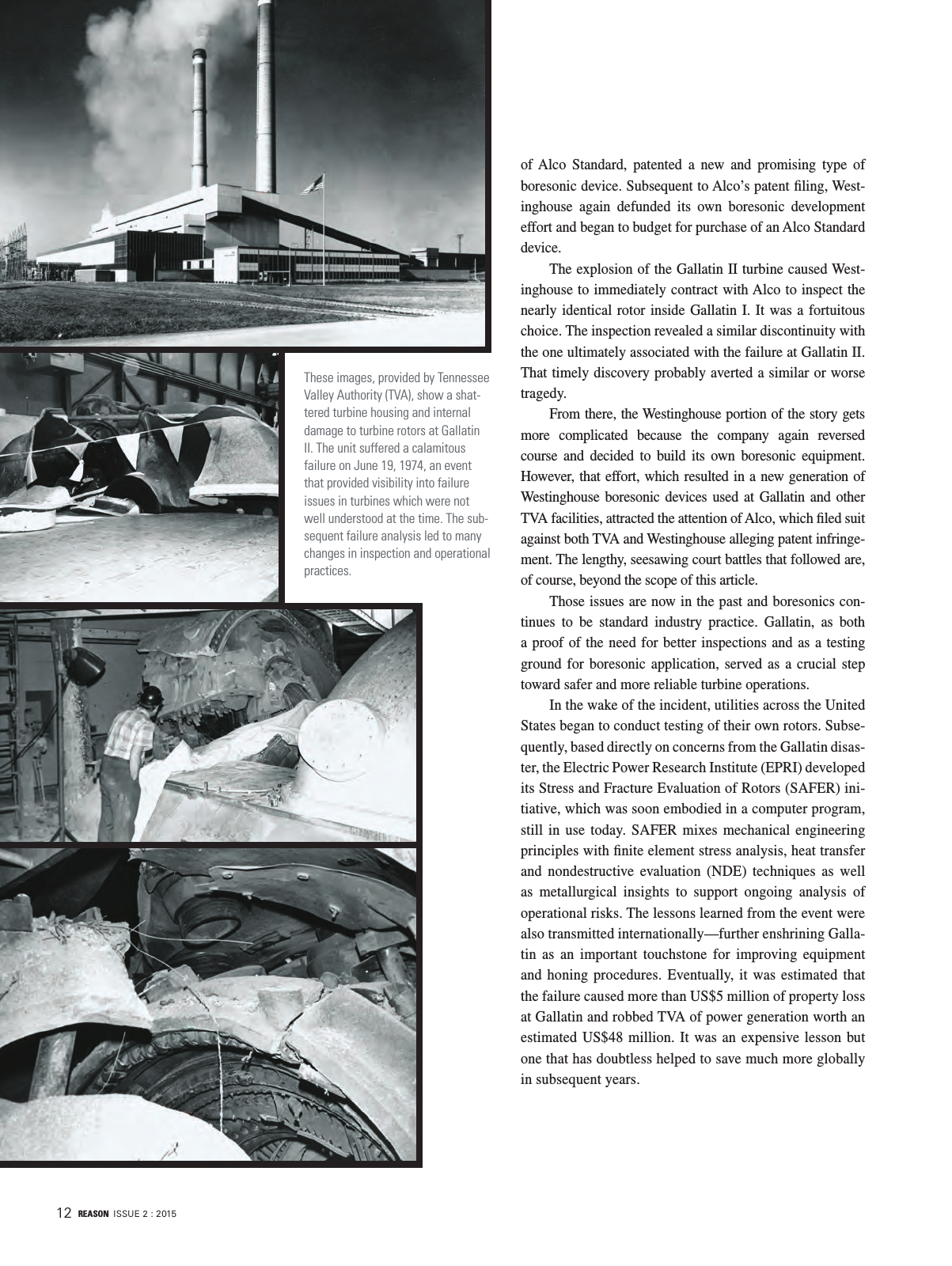

of Alco Standard patented a new and promising type of boresonic device Subsequent to Alco s patent filing West inghouse again defunded its own boresonic development effort and began to budget for purchase of an Alco Standard device The explosion of the Gallatin II turbine caused West inghouse to immediately contract with Alco to inspect the nearly identical rotor inside Gallatin I It was a fortuitous choice The inspection revealed a similar discontinuity with the one ultimately associated with the failure at Gallatin II That timely discovery probably averted a similar or worse tragedy From there the Westinghouse portion of the story gets more complicated because the company again reversed course and decided to build its own boresonic equipment However that effort which resulted in a new generation of Westinghouse boresonic devices used at Gallatin and other TVA facilities attracted the attention of Alco which filed suit against both TVA and Westinghouse alleging patent infringe ment The lengthy seesawing court battles that followed are of course beyond the scope of this article Those issues are now in the past and boresonics con tinues to be standard industry practice Gallatin as both a proof of the need for better inspections and as a testing ground for boresonic application served as a crucial step toward safer and more reliable turbine operations In the wake of the incident utilities across the United States began to conduct testing of their own rotors Subse quently based directly on concerns from the Gallatin disas ter the Electric Power Research Institute EPRI developed its Stress and Fracture Evaluation of Rotors SAFER ini tiative which was soon embodied in a computer program still in use today SAFER mixes mechanical engineering principles with finite element stress analysis heat transfer and nondestructive evaluation NDE techniques as well as metallurgical insights to support ongoing analysis of operational risks The lessons learned from the event were also transmitted internationally further enshrining Galla tin as an important touchstone for improving equipment and honing procedures Eventually it was estimated that the failure caused more than US 5 million of property loss at Gallatin and robbed TVA of power generation worth an estimated US 48 million It was an expensive lesson but one that has doubtless helped to save much more globally in subsequent years These images provided by Tennessee Valley Authority TVA show a shat tered turbine housing and internal damage to turbine rotors at Gallatin II The unit suffered a calamitous failure on June 19 1974 an event that provided visibility into failure issues in turbines which were not well understood at the time The sub sequent failure analysis led to many changes in inspection and operational practices 12 REASON ISSUE 2 2015

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.

Klicken Sie hier um zur Online-Version zu gelangen.

Klicken Sie hier um zur Online-Version zu gelangen.