Reason Magazin 2014Q3 Seite 41

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

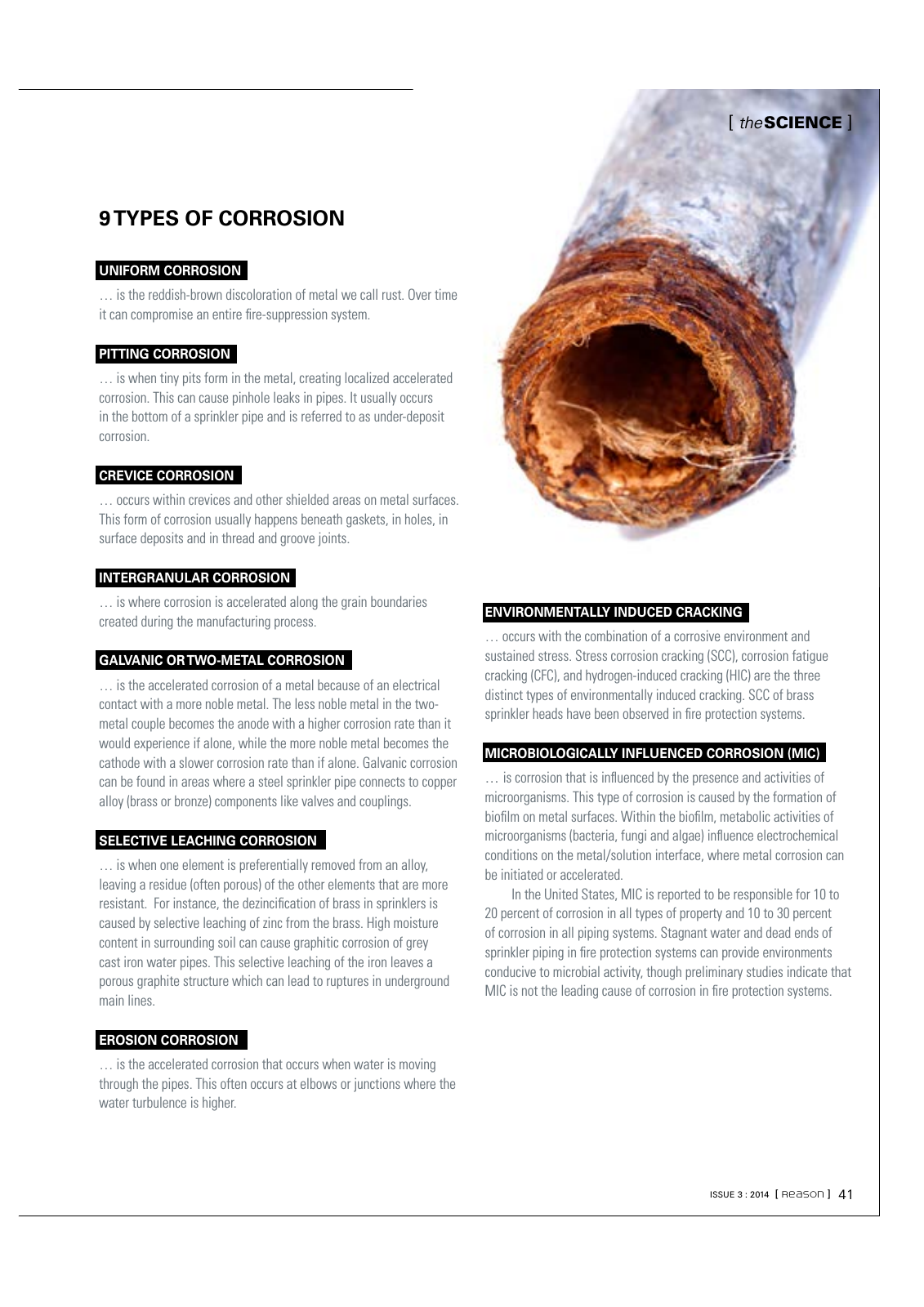

9 TYPES OF CORROSION UNIFORM CORROSION is the reddish brown discoloration of metal we call rust Over time it can compromise an entire fire suppression system PITTING CORROSION is when tiny pits form in the metal creating localized accelerated corrosion This can cause pinhole leaks in pipes It usually occurs in the bottom of a sprinkler pipe and is referred to as under deposit corrosion CREVICE CORROSION occurs within crevices and other shielded areas on metal surfaces This form of corrosion usually happens beneath gaskets in holes in surface deposits and in thread and groove joints INTERGRANULAR CORROSION is where corrosion is accelerated along the grain boundaries created during the manufacturing process GALVANIC OR TWO METAL CORROSION is the accelerated corrosion of a metal because of an electrical contact with a more noble metal The less noble metal in the two metal couple becomes the anode with a higher corrosion rate than it would experience if alone while the more noble metal becomes the cathode with a slower corrosion rate than if alone Galvanic corrosion can be found in areas where a steel sprinkler pipe connects to copper alloy brass or bronze components like valves and couplings SELECTIVE LEACHING CORROSION is when one element is preferentially removed from an alloy leaving a residue often porous of the other elements that are more resistant For instance the dezincification of brass in sprinklers is caused by selective leaching of zinc from the brass High moisture content in surrounding soil can cause graphitic corrosion of grey cast iron water pipes This selective leaching of the iron leaves a porous graphite structure which can lead to ruptures in underground main lines EROSION CORROSION is the accelerated corrosion that occurs when water is moving through the pipes This often occurs at elbows or junctions where the water turbulence is higher ENVIRONMENTALLY INDUCED CRACKING occurs with the combination of a corrosive environment and sustained stress Stress corrosion cracking SCC corrosion fatigue cracking CFC and hydrogen induced cracking HIC are the three distinct types of environmentally induced cracking SCC of brass sprinkler heads have been observed in fire protection systems MICROBIOLOGICALLY INFLUENCED CORROSION MIC is corrosion that is influenced by the presence and activities of microorganisms This type of corrosion is caused by the formation of biofilm on metal surfaces Within the biofilm metabolic activities of microorganisms bacteria fungi and algae influence electrochemical conditions on the metal solution interface where metal corrosion can be initiated or accelerated In the United States MIC is reported to be responsible for 10 to 20 percent of corrosion in all types of property and 10 to 30 percent of corrosion in all piping systems Stagnant water and dead ends of sprinkler piping in fire protection systems can provide environments conducive to microbial activity though preliminary studies indicate that MIC is not the leading cause of corrosion in fire protection systems ISSUE 3 2014 Reason 41 theSCIENCE