Reason Magazin 2014Q3 Seite 37

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

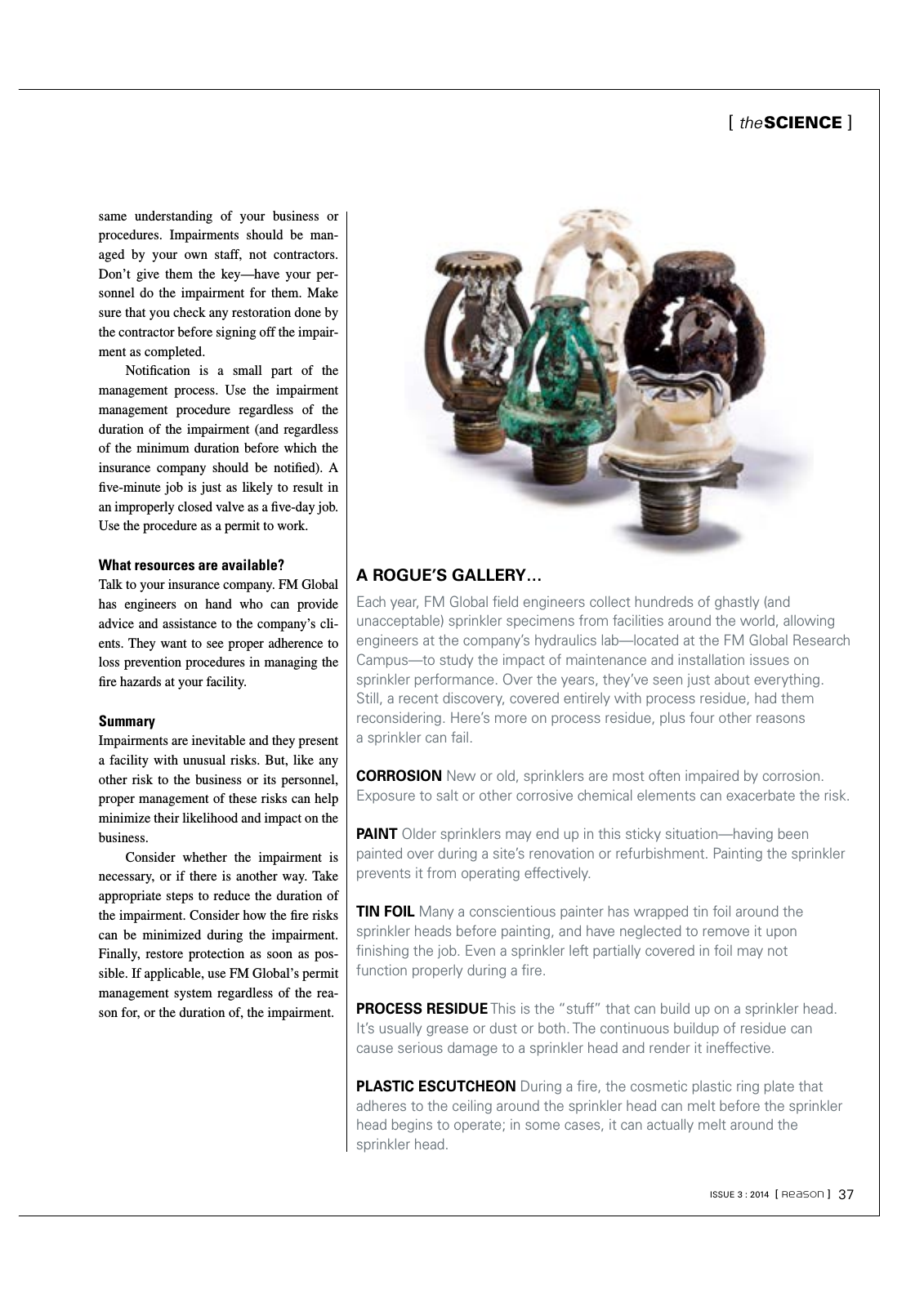

A ROGUE S GALLERY Each year FM Global field engineers collect hundreds of ghastly and unacceptable sprinkler specimens from facilities around the world allowing engineers at the company s hydraulics lab located at the FM Global Research Campus to study the impact of maintenance and installation issues on sprinkler performance Over the years they ve seen just about everything Still a recent discovery covered entirely with process residue had them reconsidering Here s more on process residue plus four other reasons a sprinkler can fail CORROSION New or old sprinklers are most often impaired by corrosion Exposure to salt or other corrosive chemical elements can exacerbate the risk PAINT Older sprinklers may end up in this sticky situation having been painted over during a site s renovation or refurbishment Painting the sprinkler prevents it from operating effectively TIN FOIL Many a conscientious painter has wrapped tin foil around the sprinkler heads before painting and have neglected to remove it upon finishing the job Even a sprinkler left partially covered in foil may not function properly during a fire PROCESS RESIDUE This is the stuff that can build up on a sprinkler head It s usually grease or dust or both The continuous buildup of residue can cause serious damage to a sprinkler head and render it ineffective PLASTIC ESCUTCHEON During a fire the cosmetic plastic ring plate that adheres to the ceiling around the sprinkler head can melt before the sprinkler head begins to operate in some cases it can actually melt around the sprinkler head same understanding of your business or procedures Impairments should be man aged by your own staff not contractors Don t give them the key have your per sonnel do the impairment for them Make sure that you check any restoration done by the contractor before signing off the impair ment as completed Notification is a small part of the management process Use the impairment management procedure regardless of the duration of the impairment and regardless of the minimum duration before which the insurance company should be notified A five minute job is just as likely to result in an improperly closed valve as a five day job Use the procedure as a permit to work What resources are available Talk to your insurance company FM Global has engineers on hand who can provide advice and assistance to the company s cli ents They want to see proper adherence to loss prevention procedures in managing the fire hazards at your facility Summary Impairments are inevitable and they present a facility with unusual risks But like any other risk to the business or its personnel proper management of these risks can help minimize their likelihood and impact on the business Consider whether the impairment is necessary or if there is another way Take appropriate steps to reduce the duration of the impairment Consider how the fire risks can be minimized during the impairment Finally restore protection as soon as pos sible If applicable use FM Global s permit management system regardless of the rea son for or the duration of the impairment ISSUE 3 2014 Reason 37 theSCIENCE