Reason Magazin 2014Q3 Seite 35

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

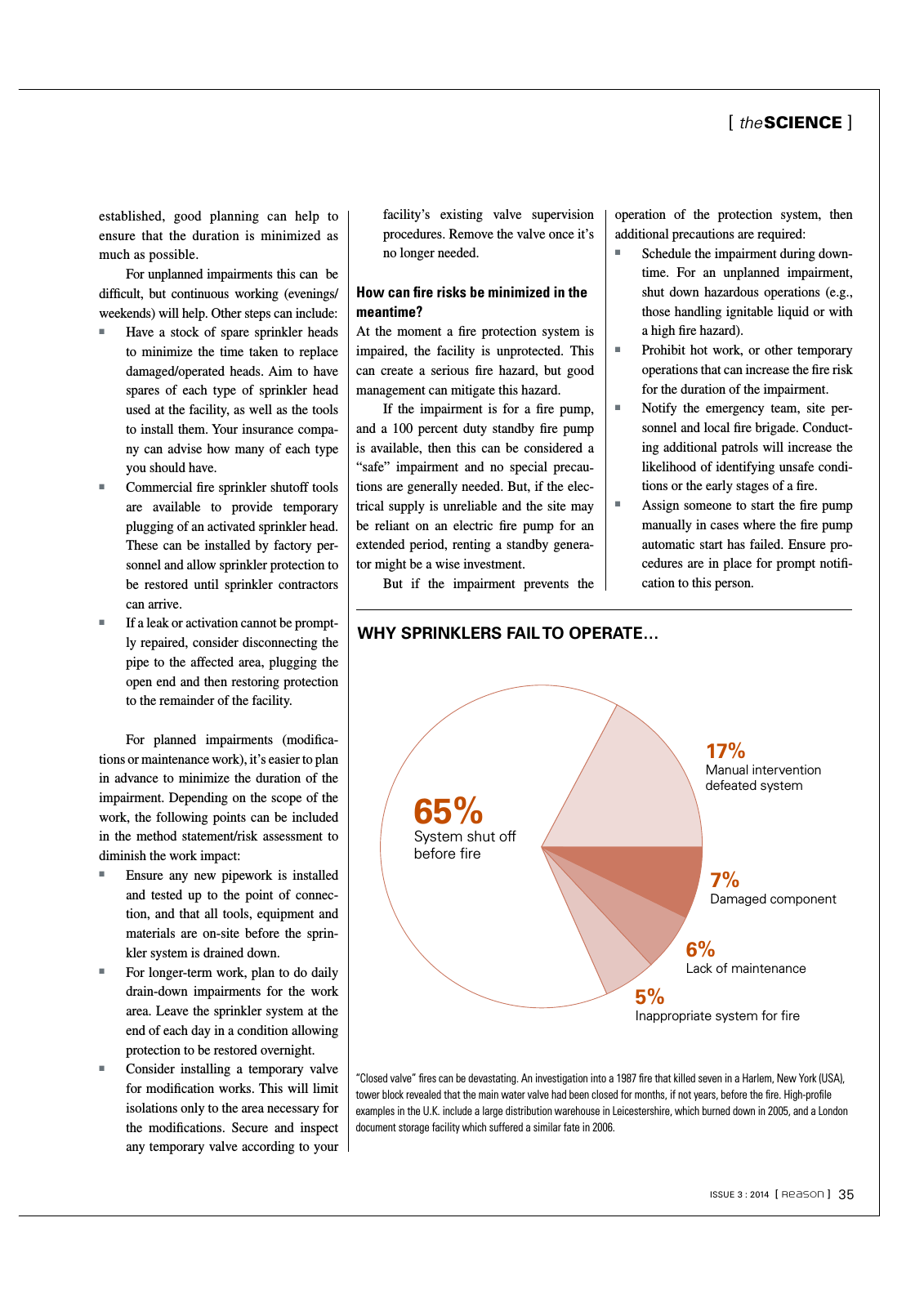

established good planning can help to ensure that the duration is minimized as much as possible For unplanned impairments this can be difficult but continuous working evenings weekends will help Other steps can include Q Have a stock of spare sprinkler heads to minimize the time taken to replace damaged operated heads Aim to have spares of each type of sprinkler head used at the facility as well as the tools to install them Your insurance compa ny can advise how many of each type you should have Q Commercial fire sprinkler shutoff tools are available to provide temporary plugging of an activated sprinkler head These can be installed by factory per sonnel and allow sprinkler protection to be restored until sprinkler contractors can arrive Q If a leak or activation cannot be prompt ly repaired consider disconnecting the pipe to the affected area plugging the open end and then restoring protection to the remainder of the facility For planned impairments modifica tions or maintenance work it s easier to plan in advance to minimize the duration of the impairment Depending on the scope of the work the following points can be included in the method statement risk assessment to diminish the work impact Q Ensure any new pipework is installed and tested up to the point of connec tion and that all tools equipment and materials are on site before the sprin kler system is drained down Q For longer term work plan to do daily drain down impairments for the work area Leave the sprinkler system at the end of each day in a condition allowing protection to be restored overnight Q Consider installing a temporary valve for modification works This will limit isolations only to the area necessary for the modifications Secure and inspect any temporary valve according to your facility s existing valve supervision procedures Remove the valve once it s no longer needed How can fire risks be minimized in the meantime At the moment a fire protection system is impaired the facility is unprotected This can create a serious fire hazard but good management can mitigate this hazard If the impairment is for a fire pump and a 100 percent duty standby fire pump is available then this can be considered a safe impairment and no special precau tions are generally needed But if the elec trical supply is unreliable and the site may be reliant on an electric fire pump for an extended period renting a standby genera tor might be a wise investment But if the impairment prevents the operation of the protection system then additional precautions are required Q Schedule the impairment during down time For an unplanned impairment shut down hazardous operations e g those handling ignitable liquid or with a high fire hazard Q Prohibit hot work or other temporary operations that can increase the fire risk for the duration of the impairment Q Notify the emergency team site per sonnel and local fire brigade Conduct ing additional patrols will increase the likelihood of identifying unsafe condi tions or the early stages of a fire Q Assign someone to start the fire pump manually in cases where the fire pump automatic start has failed Ensure pro cedures are in place for prompt notifi cation to this person WHY SPRINKLERS FAIL TO OPERATE Closed valve fires can be devastating An investigation into a 1987 fire that killed seven in a Harlem New York USA tower block revealed that the main water valve had been closed for months if not years before the fire High profile examples in the U K include a large distribution warehouse in Leicestershire which burned down in 2005 and a London document storage facility which suffered a similar fate in 2006 5 Inappropriate system for fire 6 Lack of maintenance 7 Damaged component 17 Manual intervention defeated system 65 System shut off before fire ISSUE 3 2014 Reason 35 theSCIENCE