Reason Mag Q1 2014 Seite 33

Hinweis: Dies ist eine maschinenlesbare No-Flash Ansicht.Klicken Sie hier um zur Online-Version zu gelangen.

Inhalt

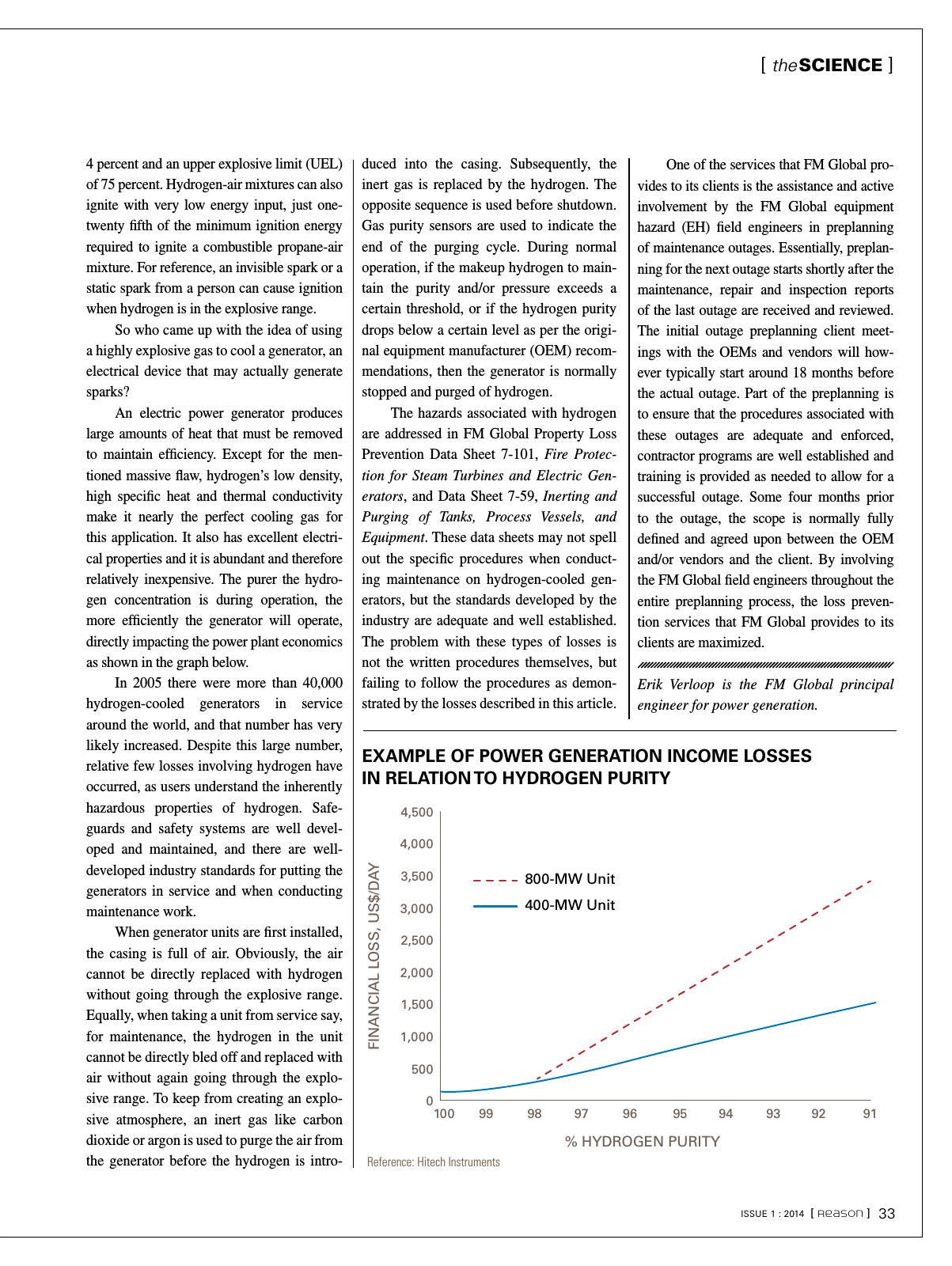

4 percent and an upper explosive limit UEL of 75 percent Hydrogen air mixtures can also ignite with very low energy input just one twenty fth of the minimum ignition energy required to ignite a combustible propane air mixture For reference an invisible spark or a static spark from a person can cause ignition when hydrogen is in the explosive range So who came up with the idea of using a highly explosive gas to cool a generator an electrical device that may actually generate sparks An electric power generator produces large amounts of heat that must be removed to maintain ef ciency Except for the men tioned massive aw hydrogen s low density high speci c heat and thermal conductivity make it nearly the perfect cooling gas for this application It also has excellent electri cal properties and it is abundant and therefore relatively inexpensive The purer the hydro gen concentration is during operation the more ef ciently the generator will operate directly impacting the power plant economics as shown in the graph below In 2005 there were more than 40 000 hydrogen cooled generators in service around the world and that number has very likely increased Despite this large number relative few losses involving hydrogen have occurred as users understand the inherently hazardous properties of hydrogen Safe guards and safety systems are well devel oped and maintained and there are well developed industry standards for putting the generators in service and when conducting maintenance work When generator units are rst installed the casing is full of air Obviously the air cannot be directly replaced with hydrogen without going through the explosive range Equally when taking a unit from service say for maintenance the hydrogen in the unit cannot be directly bled off and replaced with air without again going through the explo sive range To keep from creating an explo sive atmosphere an inert gas like carbon dioxide or argon is used to purge the air from the generator before the hydrogen is intro duced into the casing Subsequently the inert gas is replaced by the hydrogen The opposite sequence is used before shutdown Gas purity sensors are used to indicate the end of the purging cycle During normal operation if the makeup hydrogen to main tain the purity and or pressure exceeds a certain threshold or if the hydrogen purity drops below a certain level as per the origi nal equipment manufacturer OEM recom mendations then the generator is normally stopped and purged of hydrogen The hazards associated with hydrogen are addressed in FM Global Property Loss Prevention Data Sheet 7 101 Fire Protec tion for Steam Turbines and Electric Gen erators and Data Sheet 7 59 Inerting and Purging of Tanks Process Vessels and Equipment These data sheets may not spell out the speci c procedures when conduct ing maintenance on hydrogen cooled gen erators but the standards developed by the industry are adequate and well established The problem with these types of losses is not the written procedures themselves but failing to follow the procedures as demon strated by the losses described in this article One of the services that FM Global pro vides to its clients is the assistance and active involvement by the FM Global equipment hazard EH eld engineers in preplanning of maintenance outages Essentially preplan ning for the next outage starts shortly after the maintenance repair and inspection reports of the last outage are received and reviewed The initial outage preplanning client meet ings with the OEMs and vendors will how ever typically start around 18 months before the actual outage Part of the preplanning is to ensure that the procedures associated with these outages are adequate and enforced contractor programs are well established and training is provided as needed to allow for a successful outage Some four months prior to the outage the scope is normally fully de ned and agreed upon between the OEM and or vendors and the client By involving the FM Global eld engineers throughout the entire preplanning process the loss preven tion services that FM Global provides to its clients are maximized 800 MW Unit 400 MW Unit 4 000 4 500 FI N AN CI AL L O SS U S D AY 3 500 3 000 2 500 2 000 1 500 1 000 500 0 100 99 98 97 96 95 94 93 92 91 HYDROGEN PURITY Reference Hitech Instruments EXAMPLE OF POWER GENERATION INCOME LOSSES IN RELATION TO HYDROGEN PURITY Erik Verloop is the FM Global principal engineer for power generation ISSUE 1 2014 Reason 33 theSCIENCE